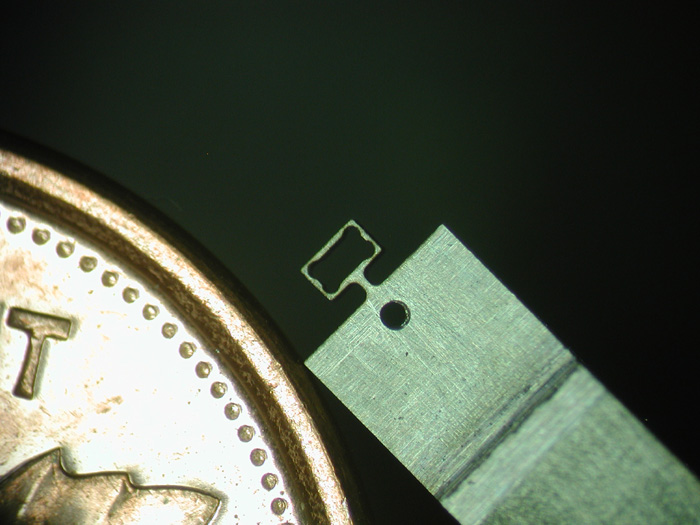

Shown are 2 shots of a micro sized medical part in 17-4 PH stainless steel. The part is micro drilled, wire EDM cut and the cut-off stub is hand finished. The part is tiny: it is 0.050″ (1.25mm) long and 0.030″ (0.75mm) wide. The wall thickness is 0.004″ (0.1mm) at the thick points and the part is accurate to within 0.0003″. It was a challenge to cut this tiny part, mostly because of the difficulty in not losing or destroying it when it was cut off from its stem.

The part still in the EDM worktank and attached by a tiny stem to the material blank. The 0.015″ start hole for the next part is also visible. The stem is 0.005″ wide

The finished, hand dressed part. Parts this small are hard to hang on to and stabilise for hand finishing. This is microscope and tweezer work, and a minor mis-step with the tweezers means you’ll never find your part again! On the right side of the shot you can see the ruby file and diamond file used to dress off the cutoff vestige from the wire EDM process. The part is the tiny black rectangle just to the left of the penny. (Click the thumbnail to enlarge it)

Recent Comments