New Wire EDM Capability: Here is a good example of what the rotary axis can do.This nitinol pin is used to hold a dental implant onto a special wrench during implant surgery. The material is very hard and also super elastic making it very difficult to machine conventionally. This tiny part was burned in one setup on the wire EDM to tolerances of +/- 0.0002” using the rotary axis in indexing mode.

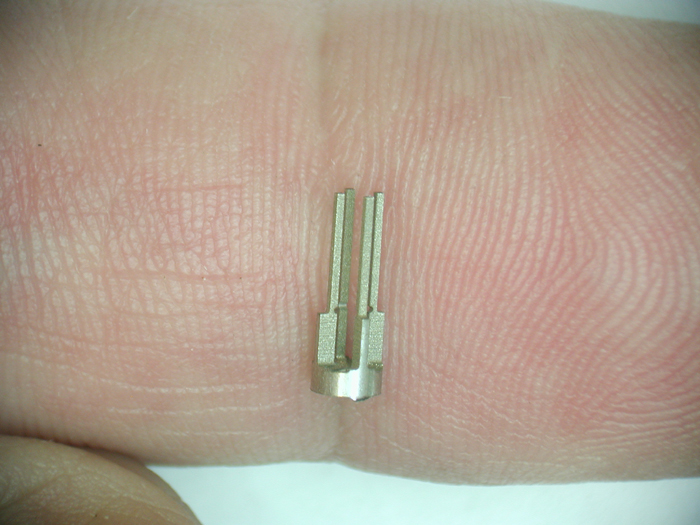

Another tiny part cut with the rotary axis. Parts like these are still expensive to cut using such a slow machining process but there is really no other way to make something like this. By the way, the little vanes are 0.015″ thick and 0.020″ wide. They will be laser welded onto a 1/16″ diameter tube, then cut free from the stub at the bottom of the picture. If you look closely, you can see a tiny notch cut into each vane…that’s where I’ll make my cut under the microscope with a diamond disc.

Shown is an experimental surgical bur used by a scientist for bone surgeries on rodents. It was one of several attempts to find the best geometry for the cutting tip. The tip is 1.8 mm diameter and has three cutting flutes. It is made from 440C surgical stainless steel. The tip geometry is created by rotating the rotary axis 180 degrees synchronously as the wire follows a curved path 4 mm long. The shank is 0.8 mm diameter and is left rough since there was no need to incur the expense to wire it to a fine finish. Overall the part is 25 mm long.

Recent Comments